“This Cincinnati, Ohio, industrial valve manufacturer has taken extensive strides to implement lean strategies to improve flow and throughput in its more than 100,000 square foot facility. In some cases, it has moved away from multitasking-type equipment to create lean, multiple-machine cells to achieve higher production.”

“In addition, Richards Industries has recently installed a a machine-monitoring system that enables shopfloor personnel to track activities and record the performance of its machine tools. The data gathered and analyzed by this system is making the company more aware of how well machine time and manpower count toward productivity. Although it is still in the early stages of implementing this system, the results are encouraging. Machine up time has increased significantly; a pallet-changing system is getting better usage, CNC programs are running more efficiently; and setup procedures have been further streamlined.”

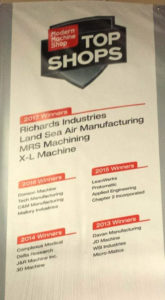

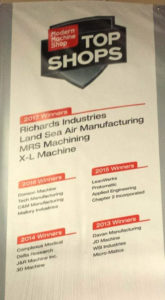

“Top Shops” is a comprehensive benchmarking program for machine shops of all types and sizes. Using data from surveys completed by a number of machining businesses, Top Shops identifies optimal shop floor practices as well as operational and business metrics that define world-class competitiveness in a discrete parts manufacturing. Companies ranging from small job shops to large captive operations can see how they compare against the country’s leading machining business which enables them to make sound decisions to emulate those identified as top-performing operations.